The ideal technique for a perfect and smooth finish

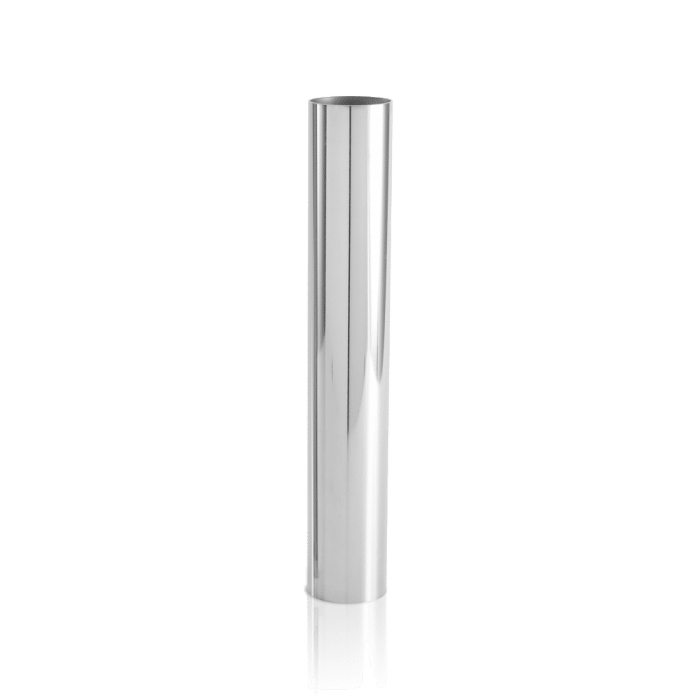

Some cutting or profiling processes produce tubes whose finish is not completely smooth, which will require to remove the ridge left on the edge (known as burr) and polish it. The pipe deburring process is the one that aims to remove the burr and polish the edges and the surface of the workpiece to achieve a completely smooth finish.

Planes carries out brush deburring and vibratory finishing. This is a service that complements the saw cutting, so that every piece leaves our facilities with a perfect finish.