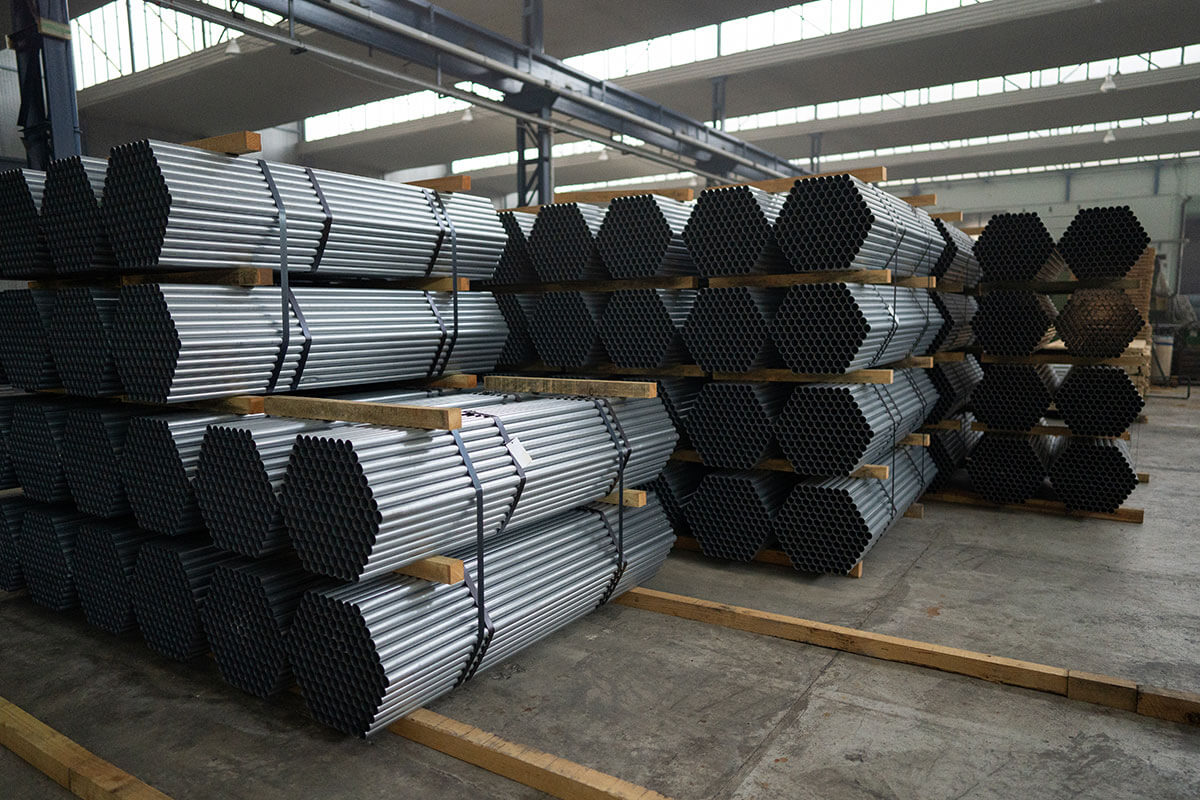

High-durability and corrosion-resistant tubes for demanding environments

Galvanised tubes are manufactured using coils subjected to zinc coating or new alloys such as Zinc-Magnesium, creating protection that significantly increases tube durability in corrosive environments. We offer a wide range of dimensions adapted to our clients' needs.

Request Information View Product Sheet