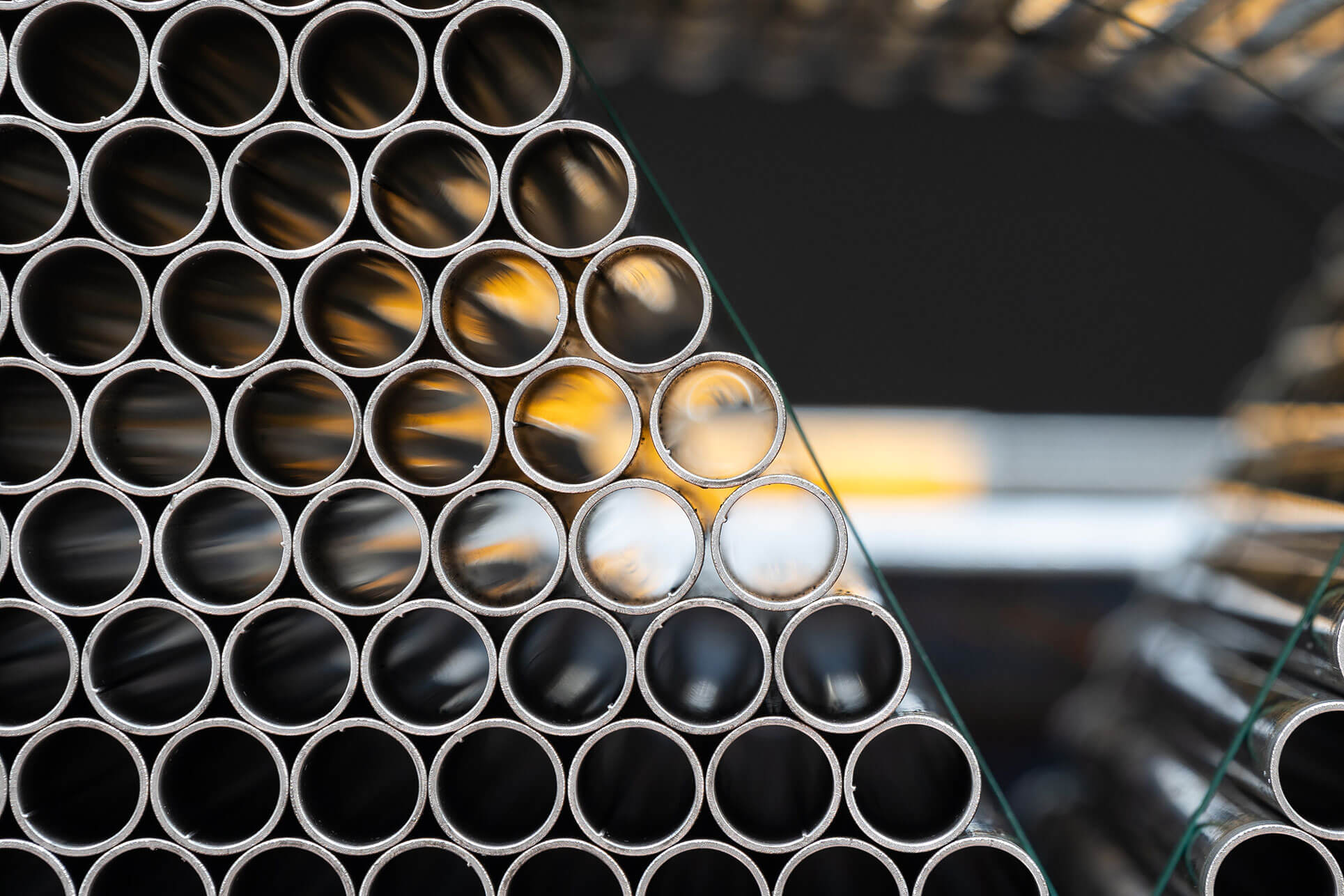

Tube pressing

We press tubes in an automated way, ensuring precision and uniformity in each piece. Our process optimises time and costs, offering high-quality finishes in different materials and diameters. Trust our advanced technology for efficient and customised solutions.

Ask for information